IMT High Rate Thickeners

IMT High Rate Thickeners

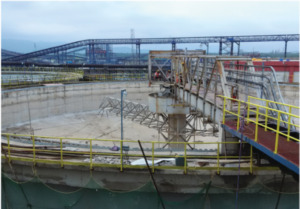

IMT offers high rate thickeners to the Mineral & Coal processing industries for water recovery and thickening applications. The applications vary from thickening the product or the tailing to recovering the water in the Blast furnace dust neutralisation systems to waste water plants. the sizes of thickeners offered range from pilot plant thickener of 1.0 m dia to 100 m dia with full bridge designs up to 45m dia and column mounted designs beyond 45 m diameter

IMT Bolted Design Thickeners

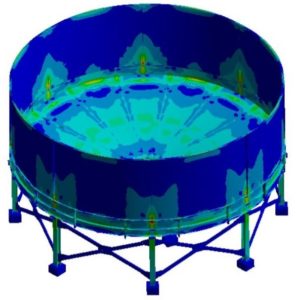

Thickener tanks are either of steel construction or RCC and latest design development has optimize the cost of the steel tank that most of the client nowadays prefers steel tank.

Design Aspects

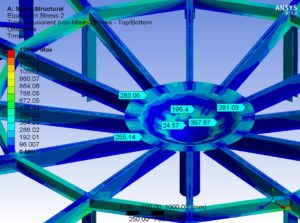

IMT carries out Finite Element Analysis for all steel tank designs so that the designs are optimized and most suited for the duty conditions. For the RCC tanks IMT extends supports by providing civil construction drawings on chargeable basis.

IMT Thickener Drives

IMT offers hydraulic drives with planetary gear boxes as a standard design with local control panels providing audio visual alarm systems for torque loads, rake mechanism lift position and high torque trip arrangements.

Mechanical drives with load cell arrangements for torque control system are offered for applications where customer does not prefer hydraulic drives.

IMT Cable Torque

Test works carried out with dynamic test unit to assist the amenability for jigging and the unit stimulates plant size jigging unit controls in a batch process.

IMT offers cable torque lift thickeners for light duty applications like blast furnace dust slurry and coal tailing where solids are very light and a simple move-over rake arrangements shall suffice for smooth operations.

Share this page

Share on WhatsApp

Share on Telegram

Email this link

Share on Facebook

Share on Twitter

Share on LinkedIn

Copy to clipboard